The success of building an intelligent supply chain depends solely on strategic optimization and seamless technology integration. In the wake of successive disruptive global events since 2020, possessing an intelligent supply chain is not merely advantageous but imperative for the prosperity of enterprises.

“Many supply chains are perfectly suited to the needs that the business had 20 years ago.”

MIT Professor Jonathan Byrnes

In this comprehensive guide, we delve into the essential steps and key considerations for navigating your path toward building an intelligent supply chain that can withstand the challenges of today’s dynamic business landscape. From harnessing the power of data analytics and artificial intelligence to adopting cutting-edge technologies like IoT and blockchain, we will explore the building blocks of a resilient and adaptive supply chain.

What is an intelligent supply chain and why do you need it?

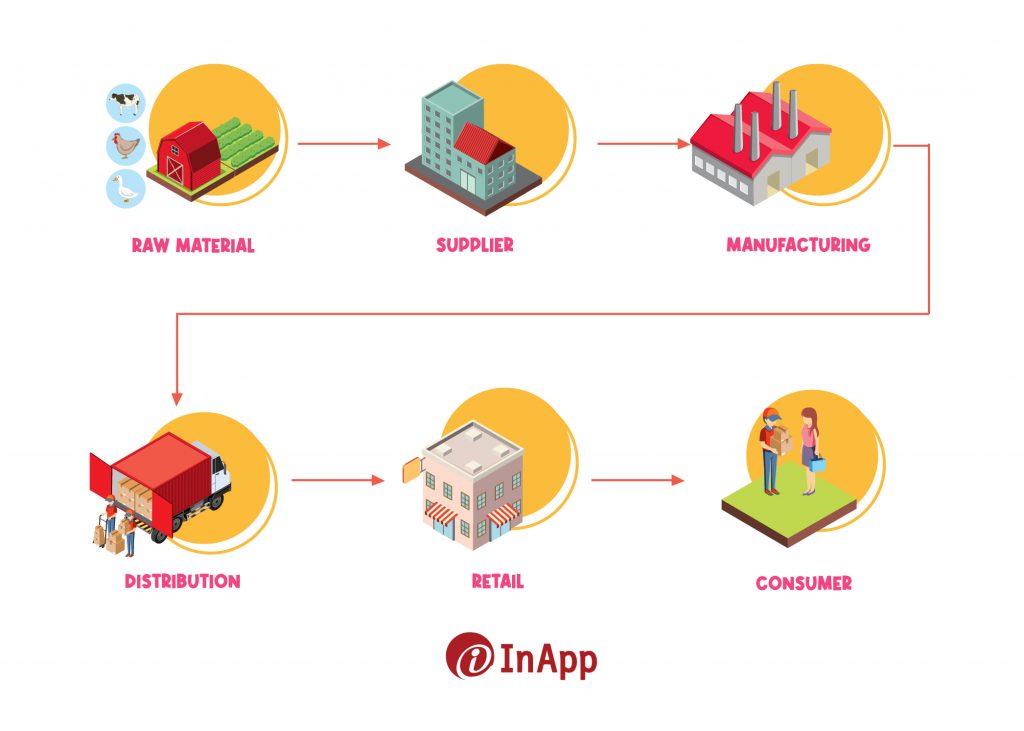

An intelligent supply chain refers to the strategic integration of advanced technologies (like AI, ML, and IoT), data analytics, and automation to optimize the end-to-end processes of supply chain management.

By leveraging real-time data, artificial intelligence, and other smart technologies, businesses can enhance decision-making, streamline operations, and respond dynamically to changing market demands.

This approach transforms the traditional linear supply chain into a dynamic, interconnected system that adapts proactively, increasing efficiency and cost savings. In short, Intelligent supply chains are characterized by their ability to predict, analyze, and optimize various aspects of the supply chain, ensuring agility and competitiveness.

Suez Canal Incident: An Intelligent Supply Chain Use Case

In March 2021, the Suez Canal’s six-day blockage triggered a global supply chain crisis, prompting companies to seek agile solutions. The resultant trade disruptions, amounting to a staggering $40 billion within that short timeframe, underscored the urgent need for resilient supply chain management.

Enter Blue Yonder, an AI-driven logistics platform that emerged as a compelling use case during this period. A standout feature of Blue Yonder was its adept analysis of data from diverse sources, including local media, weather conditions, and IoT sensors on shipment containers.

This analytical prowess helped businesses to predict with precision how the Suez Canal blockage would impact their production, sales, and overall operations. By anticipating shipment arrival times, companies could strategically manage potential disruptions.

In a world where unforeseen disruptions, such as the Suez Canal incident in March 2021, can wreak havoc on global supply chains, the need for an intelligent supply chain becomes paramount. The incident, causing a $40 billion trade disruption in just six days, highlights the vulnerability of traditional linear supply chains.

An intelligent supply chain utilizes AI, ML, and IoT to proactively analyze diverse data sources, including local media and IoT sensors. This will enable businesses to predict and strategically manage potential disruptions, ensuring resilience and agility. Companies employing these advanced solutions not only navigate challenges adeptly but also gain a strategic edge by predicting, analyzing, and optimizing various facets of the supply chain.

Five Steps to Building an Intelligent Supply Chain

The integration of an intelligent supply chain is pivotal for organizations seeking heightened efficiency, adaptability, and competitive advantage. Here are the six crucial steps that pave the way for a resilient and intelligent supply chain.

1. Technology Integration and Infrastructure Enhancement

Initiating the journey toward an intelligent supply chain begins with a complete overhaul of your existing technological infrastructure. Integration of technologies such as Artificial Intelligence (AI), Machine Learning (ML), and the Internet of Things (IoT) is foundational. These technologies, when harmoniously woven into the fabric of the supply chain, lay the groundwork for real-time data acquisition, processing, and analysis. This step serves as the cornerstone, setting the stage for subsequent advancements.

2. Data-driven Decision-Making

A pivotal aspect of an intelligent supply chain is harnessing the power of data. Leveraging advanced analytics tools will help businesses to extract meaningful insights from diverse data sets. This, in turn, facilitates informed decision-making, allowing organizations to respond dynamically to market shifts, anticipate trends, and optimize operational processes.

3. Automation for Operational Excellence

Automation stands at the heart of an intelligent supply chain, streamlining operations and mitigating risks associated with manual processes. Embracing robotic process automation (RPA) and autonomous systems enhances efficiency in routine tasks, reducing errors and increasing overall productivity. This in turn helps organizations to focus human resources on more strategic and complex aspects of supply chain management.

4. Supply Chain Visibility and Transparency

Ensuring end-to-end visibility across the supply chain is crucial for proactive decision-making. Real-time tracking of inventory, shipments, and production processes enables organizations to identify bottlenecks, anticipate delays, and optimize resource allocation. Enhanced transparency not only facilitates smoother operations but also builds trust among stakeholders and customers.

5. Continuous Improvement and Adaptability

The journey towards an intelligent supply chain is iterative and demands a commitment to continuous improvement. Organizations must embrace a culture of adaptability, incorporating feedback loops and monitoring key performance indicators (KPIs) to identify areas for enhancement. This ensures that the intelligent supply chain remains responsive to evolving market dynamics and emerging technologies.

Future of Supply Chain Technology

The role of emerging technologies is becoming increasingly pivotal in supply chain management. A recent survey by Gartner highlights that 61% of respondents recognize technology as a key resource for gaining a competitive advantage, emphasizing the critical role of emerging technologies in their investment strategies.

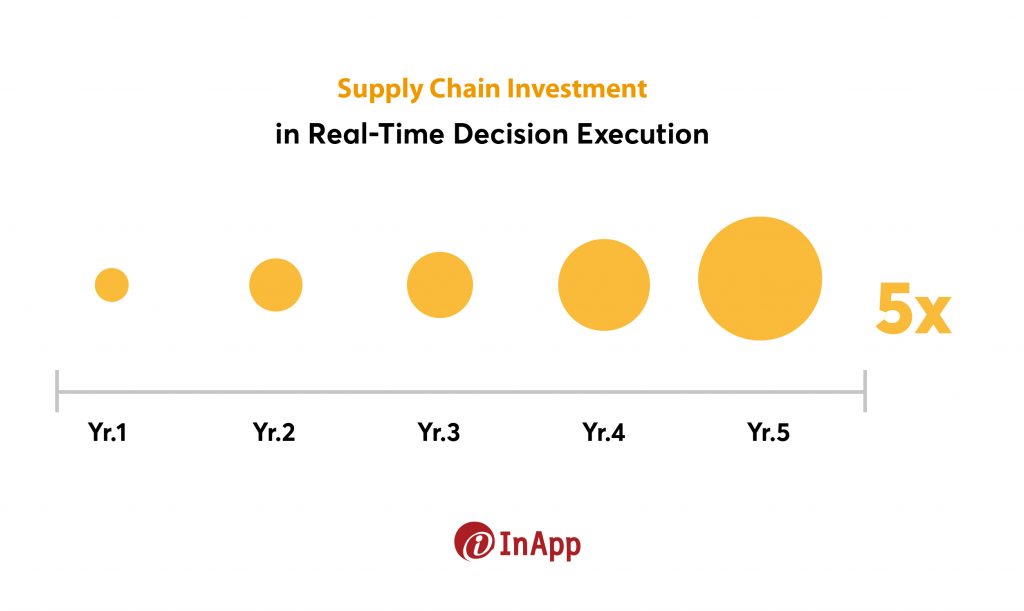

The adoption of digital supply chain technologies is anticipated to escalate rapidly over the next three to five years, aiming to enhance and streamline human decision-making processes. This shift towards digital transformation is not merely a trend but a strategic response to the demands of a modern and dynamic business environment.

Anticipated Technological Trends Shaping the Future Supply Chain Landscape

1. Intralogistics Smart Robots: A Game-changer for Warehouses

By 2026, an estimated 75% of large enterprises are expected to incorporate intralogistics smart robots into their warehouse operations (source). These advanced robots promise to revolutionize warehouse efficiency, optimizing tasks such as order fulfillment, inventory management, and logistics. The integration of smart robots not only ensures accuracy and speed but also allows human workers to focus on more complex and strategic aspects of warehouse management.

2. Embedded AI and Advanced Analytics in Supply Chain Management Apps

The future of supply chain management apps is poised to be enriched with embedded Artificial Intelligence (AI) and Advanced Analytics (AA). Approximately 75% of supply chain management app vendors are projected to deliver these intelligent features by 2026 commercially. This integration will empower organizations with predictive analytics, real-time insights, and data-driven decision-making capabilities, fostering a more responsive and agile supply chain ecosystem.

3. Control Tower Initiatives and Digital Supply Chain Twins

A staggering 80% of companies are anticipated to face severe value loss if they fail to merge control tower initiatives with digital supply chain twins by 2026 (source). The synergy between these two concepts creates a holistic and interconnected view of the entire supply chain, enabling organizations to monitor, analyze, and optimize operations in real time. The integration of control towers and digital twins is poised to become a cornerstone in building resilience and agility within supply chain management.

4. Intelligent Edge Ecosystems: Shaping Supply Chain Decisions

The advent of intelligent edge ecosystems is set to influence approximately 25% of supply chain decisions by 2025. These ecosystems, characterized by decentralized processing at the edge of the network, bring decision-making closer to the data source. This proximity enhances the speed of decision-making, reduces latency, and enables organizations to respond rapidly to dynamic supply chain conditions.

The Imperative for Supply Chain Evolution

As we venture into the future, the symbiosis between supply chain management and technology becomes increasingly evident. The integration of smart robots, embedded AI, control towers, digital twins, and intelligent edge ecosystems heralds a new era in supply chain management.

Organizations that proactively embrace these technological advancements are not only poised for competitive advantage but are also better equipped to navigate the challenges of an ever-changing business landscape. The future of supply chain technology is not just a destination, it’s a continuous journey of innovation and adaptation.

Let’s talk about building smarter networks for your business. Connect with us today for a game-changing transformation. Ready when you are!