The Internet of Things (IoT) enables manufacturing companies of all sizes to use real-time data to improve the efficiency of their operations. With IoT devices, manufacturers can collect data faster and easier than ever before. Smaller, more reliable, and more intelligent sensors for virtually all types of assets and operations are becoming more readily available at affordable prices.

But the real power of this disruptive technology lies in analytics that provides a new level of business intelligence. Modern software tools support data collection from IoT devices by analyzing real-time readings—so manufacturers can react faster and use that data efficiently to make improvements in operations.

Other industries—from healthcare to energy to transportation—are also harnessing the power of the IoT. Manufacturers would do well to pay close attention to these trends now.

How Does the IoT Affect Manufacturers?

As technology becomes less expensive and gets more powerful, an explosion of IoT devices is flooding the marketplace. The post-COVID-19 global IoT market size is expected to grow from USD $300.3 billion in 2021 to USD $650.5 billion by 2026, at a compound annual growth rate (CAGR) of 16.7% from 2021 to 2026, according to a recently published report by Markets and Markets. By component, the software solutions segment is expected to have the largest market share during the forecast period.

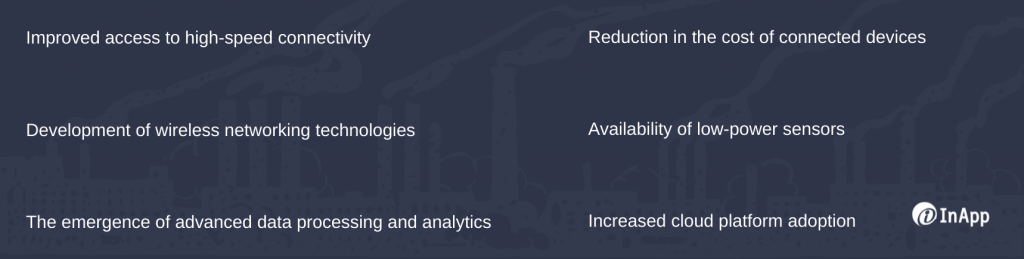

Factors spurring that growth include…

- Improved access to high-speed connectivity

- Development of wireless networking technologies

- The emergence of advanced data processing and analytics

- Reduction in the cost of connected devices

- Availability of low-power sensors

- Increased cloud platform adoption

So what does this mean for manufacturers? It means more data—a lot more data—and more data in real time. And more real-time data means better insights into your operations, including what’s working, what’s not, what’s costing you money, and the best place to invest more resources.

The Powerful Combination of the IoT and Custom Software

The true power of the IoT isn’t actually in the sensors and devices themselves. It’s the software that stores and processes the data that makes the difference. As part of the digital transformation process, manufacturers can make sense of what to do with the data gathered by these devices, telling them to take action when the time is right.

With the IoT, big data becomes even bigger. The key is finding a way to use that data to manage your operations. The combination of the IoT and custom software can improve the way operate, monitor, control, and maintain manufacturing operations. The long-term goals of the IoT and custom software are improved efficiency, better customer service, identification of new revenue-generating opportunities, and enhanced safety.

Hence, custom software development is expected to become an increasingly popular business investment during the next few years. Manufacturers already use custom software solutions and a wide range of technologies to meet objectives and maintain a crucial competitive edge, such as automating functionality in manufacturing facilities. Additionally, companies are investing in software to control operations from remote locations, something that’s particularly helpful for organizations with multiple sites.

Common Challenges with the Internet of Things

Experience

Big data analytics provide a means of turning the ever-increasing stream of asset data into actionable information. However, implementing the IoT means more data (a great deal more) in real-time, and your personnel will need training to take advantage of the value these data streams deliver. That requires new skill sets for your employees, which includes investments in training and educational programs.

Technology

Companies cannot readily incorporate new features and improvements in older software, sensors, and hardware. Limited integration between internal systems (managerial apps, plant data sources), and external partners also creates data silos. However, network connectivity is rapidly improving across factories and other facilities, and a wider range of providers is offering higher-capacity, lower-cost cloud-based storage.

Security

The number one challenge to IoT implementation is security. Aging operating systems and vulnerable operational technologies pose security risks because they cannot be easily retired or replaced. As technology evolves, however, so does security. Best practices and a wide array of evolving technologies can help companies minimize risk. Additionally, organizations don’t necessarily need to expose metrics or controls to the Internet to move forward. While this doesn’t eliminate the threat altogether, it does lessen it considerably.

Infrastructure

The IoT is simultaneously changing infrastructure components in both the private and public sectors. In the future, the IoT will likely provide closer connections between private businesses and governments in areas such as transportation, utilities, energy conservation, facility management, and more. While some regions face challenges in replacing legacy infrastructures, over time this transition will likely accelerate as new innovations make it more feasible both financially and operationally.

Have questions about how the IoT can help your business? Contact the experts at InApp. We can help.

Frequently Asked Questions

What is the Internet of Things?

Sometimes called the Industrial Internet of Things or Industrial Internet, the IoT describes systems that gather information directly from multiple devices, which can be almost anything with a sensor—including computers, vehicles, smartphones, appliances, building automation systems, and production equipment. Despite the name, you don’t need the Internet to use an IoT device. Instead, they typically send data to other devices via a wireless network connection or the wired local area network (LAN).