The manufacturing industry has been digitalizing its operations since the emergence of the internet and modern computer technology. As a result, the industry possesses terabytes of data collected from their machines on the factory floor. But for a long, they didn’t know what to make of that data. Not any longer!

With the application of Artificial Intelligence-powered systems, manufacturing organizations have started using the data collected over years to increase their efficiency and reduce costs. Now, AI is considered to be a game-changer at every level in manufacturing. Every industry is supposed to be affected dramatically by AI within 10 years.

By 2025, the continuous and wide availability of data combined with intelligent algorithms will charge up the manufacturing industry. It’ll enable higher production and better quality through optimizations of resources and reduction of overall waste by up to 50%, according to this report by the World Economic Forum.

But how Artificial Intelligence does this? In simple terms, AI performs an action, learns from the results, and adjusts its next actions to achieve better results. Looks simple, but this is a technological revolution in manufacturing. The organizations adopting it faster will stay ahead of their competitors in terms of overall profitability and better product launches.

Factors Driving the Adoption of Artificial Intelligence

- Need for continuous cost savings

- High revenue volatility

- Short production time

- Need for increasing manufacturing capacity

- Increasing regulations

- Supply chain demands

- Rising need for customized goods

By collecting data from sensors installed on machines and tools, the use of edge analytics powered by AI offers faster and more decentralized insights. It helps in improving quality and yield, tracking workers’ health and safety, and detecting early signs of failures.

What are the 6 Ways Artificial Intelligence is Improving Manufacturing

Predictive maintenance

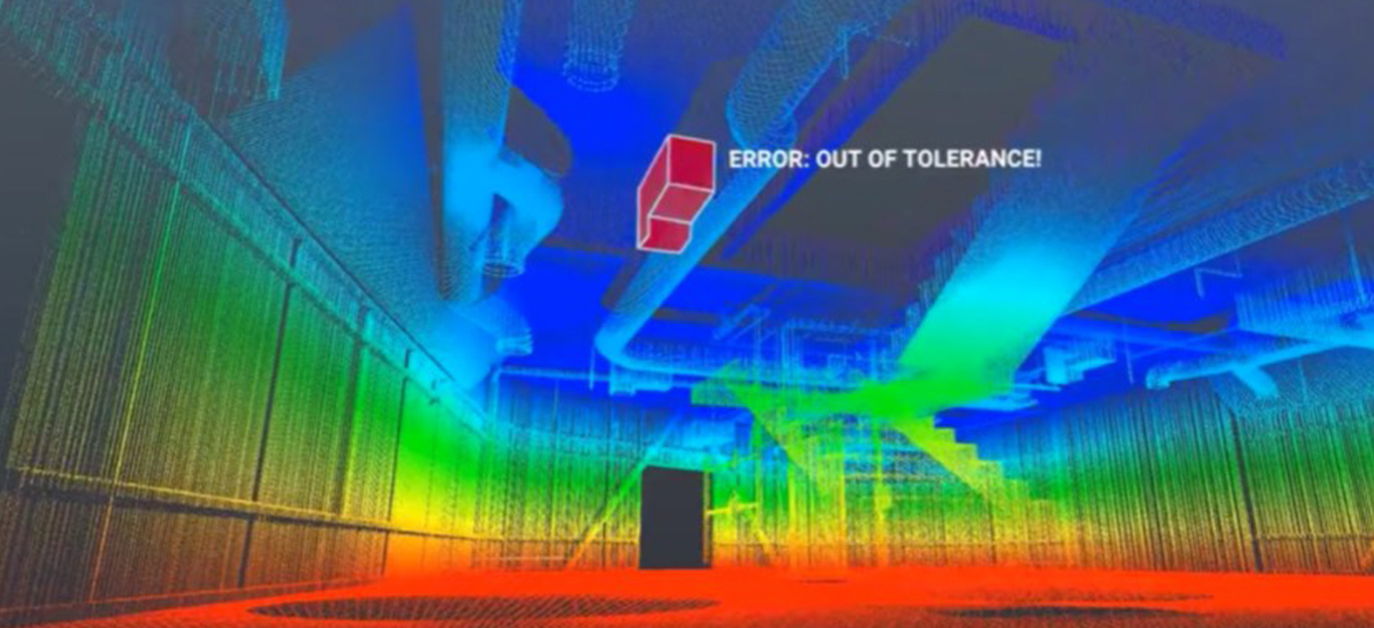

AI-based predictive maintenance helps manufacturers forecast when their equipment and machinery may fail. With this data, they can schedule their maintenance and repair work in advance. That helps in reducing costs and improving efficiency. This also helps in identifying downtimes and potential accidents in advance. Thales SA has already deployed AI to predict preventive maintenance for high-speed rail lines across Europe. And Nokia has launched a machine learning-based video application that alerts operators if it finds inconsistencies in the production process.

Direct automation

The industrial Internet of Things (IIoT) integrates manufacturing processes and devices on the factory floor with big data. Manufacturers are using precision sensory equipment to generate, record, and analyze data covering every aspect of production from packaging to item picking to temperature. Also, the end to end automation is leading to greater operational efficiency.

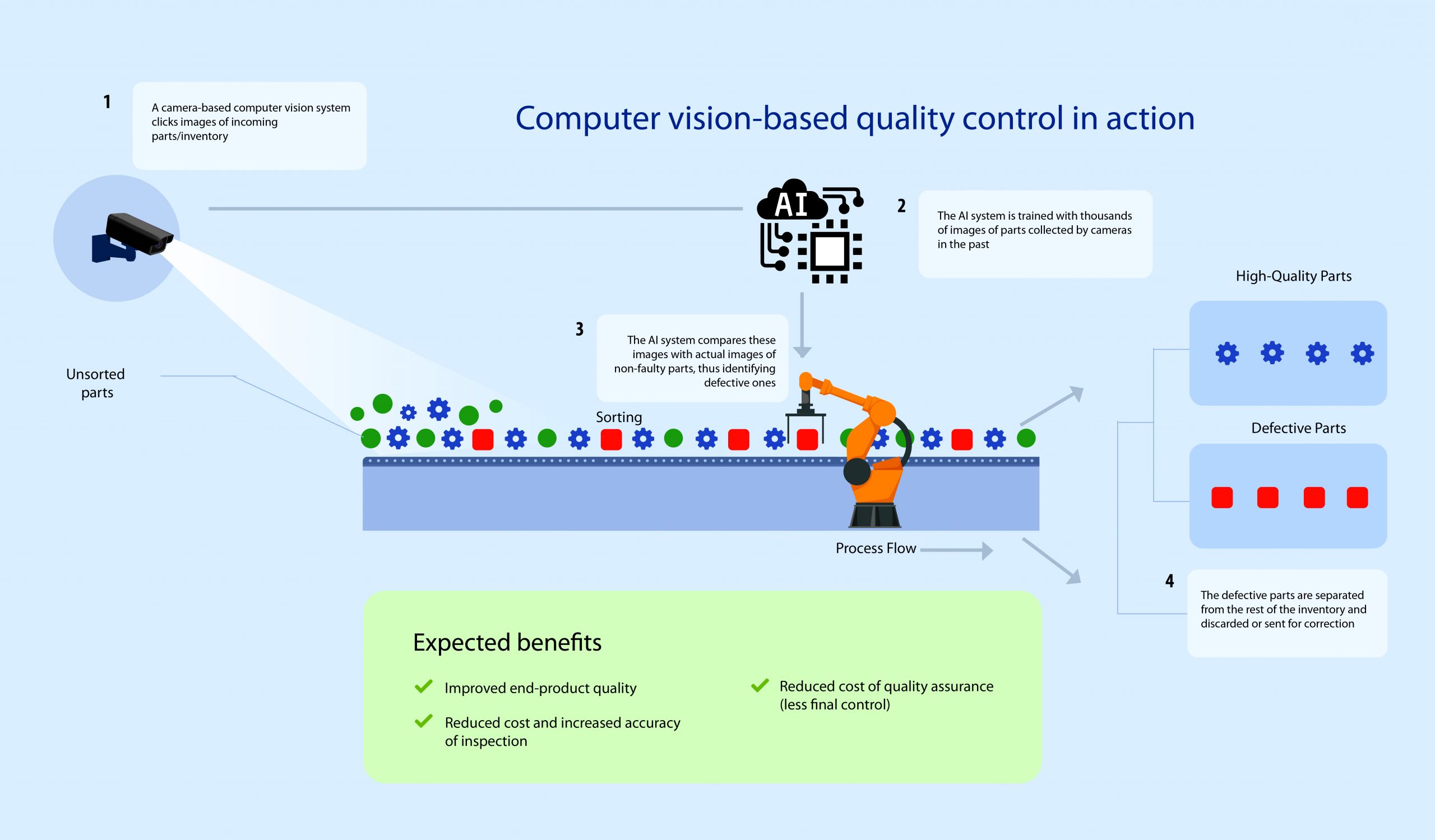

Quality assurance

Quality assurance was always a manual job. It needed skilled engineers to ensure that all electronics and microprocessors were produced correctly. With AI-powered image processing algorithms, engineers are now automatically validating whether a perfect item is produced or not.

If an end-product is of substandard quality, the Artificially Intelligence system triggers an alarm for adjusting the parameters for a better product. Canon’s Advanced Defect Recognition system is bringing new levels of quality control to its production processes. The BMW Group is evaluating component images from its assembly lines using Artificial Intelligence to spot any deviations from quality standards.

Generative design

Machine learning algorithms help organizations in designing products. By entering parameters of design such as size, strength, weight, material, etc. into generative design software, design engineers have thousands of design options for a single product. Finally, using Artificial Intelligence algorithms, engineers can iteratively improve each outcome. General Motors has implemented AI-based generative design algorithms for its optimized product design.

Safety

Manufacturing is one of the highest-risk sectors. The use of robots in the high risks operations is helping manufacturers reduce accidents, fatalities, and injuries. Schneider Electric has created predictive IoT analytics which improves workers’ safety.

Cost Reduction

Artificial Intelligence systems help in reducing the operating costs of manufacturers in many ways. AI can raise an organization’s analytics capability and help them in using their resources more efficiently, reduce inventory costs, and make accurate forecasts. The use of predictive maintenance is resulting in lowers costs through the elimination of downtime and maintenance costs. Caterpillar’s Marine Division is saving US$ four hundred thousand per ship annually by using an AI system on hulls.

Conclusions

Manufacturers frequently face different challenges such as defective products or unexpected machinery failure. By deploying AI-powered systems, they can surmount most of these challenges and also launch new better products, improve operational efficiency, reduce costs, and design customized products.

AI systems are increasing in popularity. Around 51% of manufacturers in Europe, 50% in Japan, and 28% in the US are already using AI in their production, according to Capgemini’s research. If you have any questions or would like to consult InApp’s experienced AI team, please contact us here.

Frequently Asked Questions

How does Artificial Intelligence improve manufacturing?

Artificial Intelligence systems assist manufacturers in forecasting the failure of functional equipment. With this knowledge, the companies can schedule maintenance and repair in advance. AI is also helping to reduce costs and improve operational efficiencies.

What companies use AI for manufacturing?

Some of the companies using AI are:

- GE

- General Motors

- Nissan

- Nokia

- Nike

Why robots is important in manufacturing?

Robots are doing some of the mundane, repetitive, and dangerous work in the manufacturing industry. Thus, they’re helping in creating safe conditions for workers.

How do you use Artificial Intelligence in supply chain management?

- AI is improving efficiencies in planning and predictive demand

- Chatbots are providing better customer support

- Genetic algorithms are reducing delivery times and costs