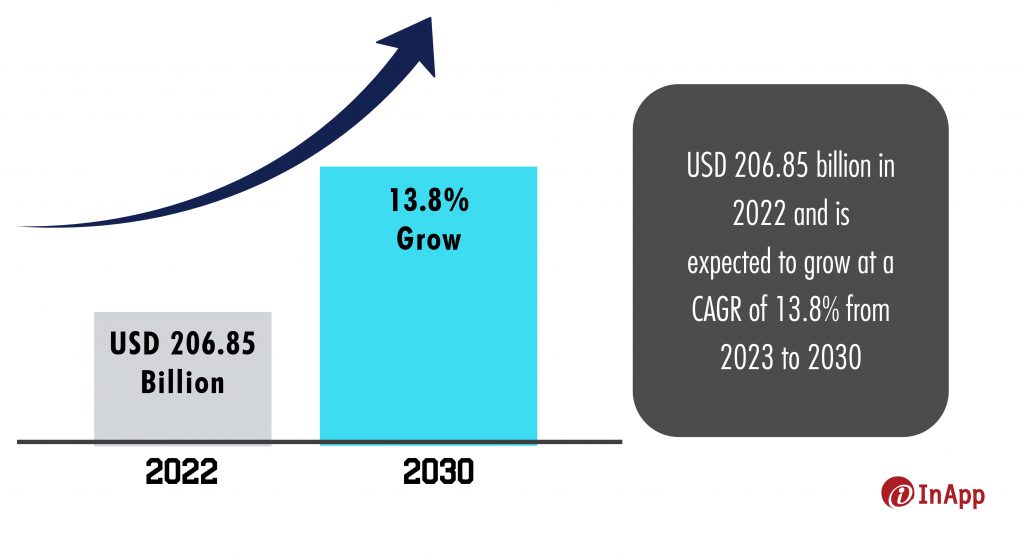

The global mobile application market size was valued at USD 206.85 billion in 2022 and is expected to grow at a CAGR of 13.8% from 2023 to 2030 (source). These winds of change have hit the manufacturing industry too.

Today, mobile apps are spearheading the revolution that is transforming the manufacturing landscape tremendously. Mobile applications are redefining the way manufacturing processes are executed, monitored, and optimized, leading to heightened efficiency, productivity, and cost-effectiveness.

With the availability of specialized manufacturing apps increasing, industries worldwide are embracing this technological revolution to stay ahead of the competition and drive unprecedented progress in their production capabilities.

In this article, we will have a deep dive into how the manufacturing industry is harnessing the power of mobile apps to propel it into a promising era of heightened productivity and sustainable growth.

Advantages of incorporating mobile apps in the manufacturing landscape

Mobile apps have emerged as a game-changer in the manufacturing sector, revolutionizing traditional processes and enhancing overall operational efficiency. Here are the key advantages of incorporating mobile apps in the manufacturing landscape:

1. Real-time Data Access and Analysis

The biggest advantage of having a mobile app is instant access to critical production data, supply chain information, and real-time analytics. Stakeholders can monitor production metrics, inventory levels, and quality control parameters on the go, facilitating swift decision-making and proactive issue resolution. This ability to analyze data on mobile devices empowers manufacturing teams to identify inefficiencies, predict maintenance requirements, and optimize workflows for continuous improvement.

2. Improved Communication and Collaboration

Mobile apps foster seamless communication and collaboration among different stakeholders in the manufacturing ecosystem. From workers to managers, suppliers, and customers, everyone can stay connected through chat functionalities, notification systems, and shared document repositories, ultimately driving higher productivity and customer satisfaction.

3. Enhanced Inventory Management:

With mobile apps business owners, logistic managers, and other stakeholders can do real-time tracking of inventory levels, materials usage, and supply chain movements. This increased visibility ensures that the right materials are available at the right time, minimizing stockouts and reducing excess inventory costs. Apart from these, mobile apps with predictive inventory algorithms can optimize procurement processes, helping manufacturers maintain optimal stock levels and avoid production bottlenecks.

4. Remote Monitoring and Maintenance

Mobile apps that come integrated with IoT allow remote monitoring and control of manufacturing equipment and machinery. Engineers and maintenance teams can receive alerts and diagnostic data on their mobile devices, facilitating proactive maintenance and minimizing downtime. Predictive maintenance capabilities also help prevent unexpected breakdowns, extend equipment lifespan, and reduce maintenance costs.

5. Increased Workforce Productivity

Unlike traditional processes, mobile apps provide workers with instant access to work instructions, training materials, and troubleshooting guides. Employees can easily report issues and receive real-time feedback, reducing the need for manual paperwork and enhancing overall workforce productivity. Training and onboarding processes can also be streamlined through mobile apps, ensuring a skilled and efficient workforce.

Mobile apps have become indispensable tools in the manufacturing sector, driving efficiency, agility, and competitiveness. As technology continues to evolve, embracing mobile app solutions will remain a key factor in transforming the manufacturing landscape and staying ahead in the ever-evolving global market.

Role of Mobile Applications in Lean Manufacturing

Lean manufacturing is a production philosophy that focuses on maximizing efficiency and eliminating waste in all aspects of the manufacturing process. Rooted in the Toyota Production System, it aims to optimize resources, minimize inventory, and deliver high-quality products to customers with the shortest possible lead time. Here is how mobile apps facilitate lean manufacturing.

1. Giving Access To Real-Time Data

Mobile apps act as indispensable tools in lean manufacturing by providing real-time data access and analysis. With mobile devices in hand, employees and stakeholders can instantly access critical production data, performance metrics, and process information.

2. Improved Communication & Collaboration

Efficient communication and collaboration are vital for lean manufacturing, and mobile apps excel in fostering seamless interaction among team members. These apps facilitate quick and effective communication, enabling workers to share ideas, discuss challenges, and implement continuous improvement initiatives.

3. Enhanced Inventory Management

Mobile apps also contribute significantly to inventory management in lean manufacturing. With real-time inventory tracking, workers can access material availability instantly, ensuring the right parts are available at the right time. This minimizes inventory holding costs, reduces the risk of stockouts, and optimizes production schedules, aligning perfectly with Lean’s emphasis on waste reduction.

4. Democratization of Workforce Training

Lean manufacturing thrives on a well-trained and empowered workforce. Mobile apps provide an ideal platform for delivering training materials, standard work instructions, and visual aids to workers, ensuring they have the knowledge and resources needed to execute their tasks efficiently. These apps also enable easy tracking of employee performance and enable rapid feedback, allowing for immediate adjustments and improvements.

Mobile Applications – The Way Forward

With mobile apps, the manufacturing industry is experiencing a transformation that fosters innovation and competitiveness. As mobile app developers continue to push the boundaries of innovation, the manufacturing sector is primed to witness even greater advancements in automation, data analytics, and interconnected smart systems, ushering in a new era of transformative possibilities.

If you are planning to invest in a mobile application for your manufacturing business, get in touch with us!